-40%

1 pc Screen Printing Machine-One Color Screen Printer for Hard Hat DIY Pattern

$ 191.08

- Description

- Size Guide

Description

新建网页 3新建网页 2

SPE-AQM240 One Color Safety Helmet Hard Material Caps Screen Printing Machine

The machine is mainly used for printing various cambered surfaces and irregular caps made of hard materials such as plastics and metals. Such as safety helmet, motorcycle helmet, etc., It can effectively improve the printing quality, improve the printing efficiency.

The hard material cap has the characteristics of unbending and different shapes, so the positioning of the hat is very difficult, resulting in inaccurate printing position. The printing surface is cambered surface with various bending degrees, irregular bending, diverse cap shapes and other special characteristics. The difficulty in fixing the cap and fitting the camber screen plate for different cap bodies in printing results in the very low printing efficiency of such caps and the difficulty in guaranteeing the printing quality.

The screen printing machine designed by our company can basically solve the above two difficulties:

Positioning of the bottom of the hat: the bottom of the hat shall be positioned in an all-round way by the shaping resin to ensure the stability of the bottom of the hat; Any material, any shape of the hat can be accurately positioned;

Positioning of the lower part of the hat: the positioning of the bottom is completed. The secondary four-point positioning and locking are adopted in the lower part of the hat to ensure that the hat will not move after it is placed in the positioning position of the printing press. At the same time to ensure that the hat is easy to take off; Easy to put the hat, the hat does not deviate;

Stainless steel cambered plate can be bend a little from left to right in accordance with the arc of the hat ; To meet the radian requirements of the cap printing surface, so as to ensure that the screen plate and printing surface arc as parallel as possible, to ensure accurate printing positioning and the quality of printing.

Basic functions of the machine:

The bottom of the machine and the positioning platform can be moved back and forth, and a drag positioning device is set; Pull the platform out before putting the hat and push into the machine after the hat put into . Pulling out and pushing in can be accurately positioned by positioning ball screws on both sides of the platform;

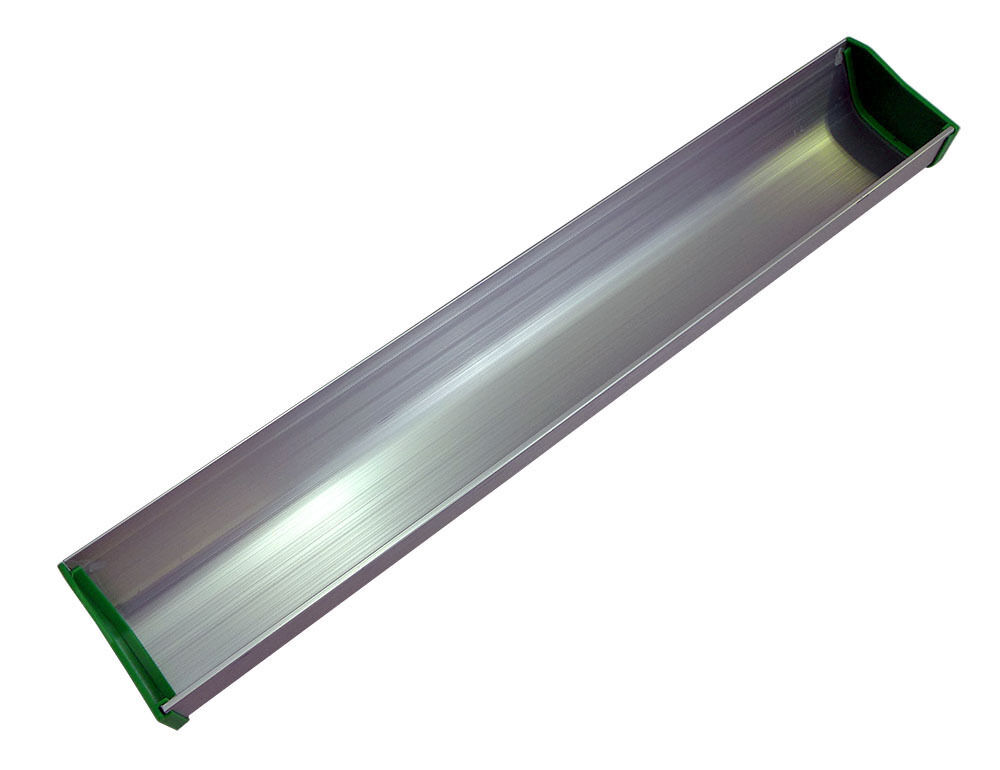

The bottom of the stainless steel plate is equipped with a large area of magnetic plate, which can be directly adsorbed on the platform. You can push and pull the plate with a little force to move on the platform (screws and nuts can also be installed in the 8 long holes on the platform after positioning the plate to block the four sides of the plate for more stable positioning);

The main machine can be micro adjusted by manual knobs from left to right , up and down,up and down can move 170 mm; There is with a handle lock; Left and right can adjust 20mm,tighten and lock.

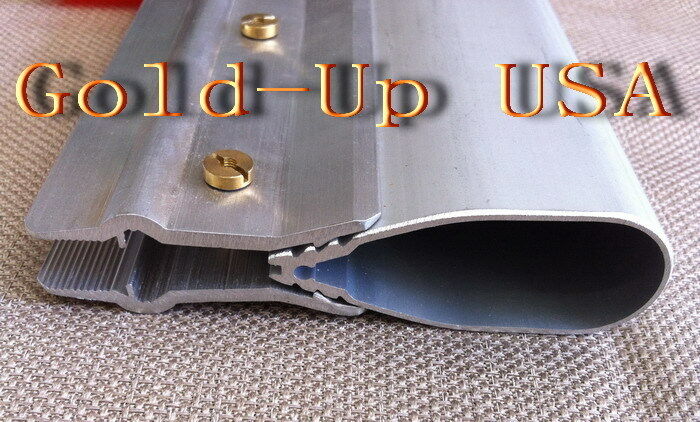

The machine adopts 1 mm stainless steel plate, the screen frame directly fixed on both sides of the frame beam; Screen plate can move 130mm front and rear; Screen plate installation beam can finished by adjusting the screen radian by hand screw; After adjusting to the same radian as the printing surface, lock the screws at both ends of the two beams.

The shaping resin has the characteristics of softening by heating and hardening by cooling; After heating to 60-100 degrees Celsius, the resin softens , place and press the bottom of the hat into the resin; After the resin cools and hardens, remove the hat, leave the outer contour shape of the hat inside the resin, and complete the positioning of the bottom. This type of resin can be repeatedly heated and cooled (user can choose electric oven heating or high temperature hot air gun heating, also can use our company supporting SPE- arc screen special heating drying cabinet).

The machine is equipped with two flexible stainless steel frames; Inner size is 100*190 mm (outer size is 130*200 mm); 100*240 mm (outer size 130*250 mm); Suitable for most kinds of hard hat printing patterns.

All parts of the machine are advanced electrostatic spraying surface treatment, corrosion resistance, acid and alkali resistance, cleaning resistance, long - term use without rust.

Supporting equipment of the machine (optional according to the need, details of supporting equipment see the relevant webpage):

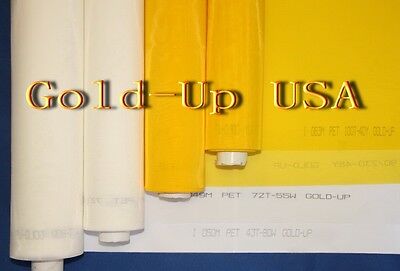

SPE-3040 special stretcher for arc-surface screen plate: due to the softness of arc-surface screen plate , normal stretcher cannot be used; This stretcher is specialized in stretching mesh of arc screen plate; It can stretch 2 arc screen plates with the outer size of 130*250 mm at the same time.

SPE- cambered screen plate special coating emulsion machine: because the arc screen plate of stainless steel only 1 mm thick, edge only 15 mm, relatively soft, traditional coating photosensitive emulsion can not ensure the smooth coating, the machine is specially designed for the arc screen plate, only used with the screen plate matching.

SPE-arc screen plate special drying cabinet: this machine is used for two purposes: one is specially drying the arc screen plate after degreasing and cleaning ; The second is used to heating the soft resin.

SPE-4632SBJ exposure unit: cambered screen plate can be suitable for a variety of exposure unit ; This exposure unit is not a special supporting equipment. This machine can place 3 cambered screen plate at the same time with the out side of 130*250 mm .

Usage methods and procedures (for reference only)

1.

Heating the shaping resin until soft and put it on the lower platform of the machine; And push into the machine to position;

2. Install the screen frame with blank mesh on the frame rack;

3. Cover the bottom of the hat with teflon cloth and press it into the shaping resin, adjust the radian of the screen frame and the printing arc of the hat, and basically determine the position of the printing pattern on the screen;

4. Adjust the positioning position of the hat, and push the soft resin beside to the four sides of the hat by hand to strengthen and fix;

5. After the resin is cooled, hold the four positioning handles of the second-floor platform against the four fixing points in the lower part of the hat and lock them.

6. Take out the hat, take out the teflon cloth, the hat positioning is completed (special note: after the positioning is completed, do not move the positioning resin tray).

7.Take down the screen plate and make plate according to the position of the pattern;

8.

In order to prevent ink overflow, screen plate around can be affixed with sealing strip;

9.Install the finished screen plate and adjust it to the appropriate position ,Install the fixed screws on both sides of the screen plate to lock and print.

Item included(006600):

1*SPE-AQM240 One Color Safety Helmet Hard Material Caps Screen Printing Machine

Shipping & Handling Details

Default Shipping Cost or Free Shipping Information:

▲

Default shipping cost or free shipping service is only for the lower 48 United States by UPS Ground or USPS. Other areas or needs other shipping ways, please contact us.

▲

Buyers from Guam, Puerto Rico, Virgin Islands, American Samoa, Alaska, Hawaii, PO Boxes, APO/FPO addresses or other countries/areas,

there WILL be extra shipping costs, please contact us for more detailed information.

▲

Please make sure your address is valid for both UPS and USPS services. Any costs incurred because of incorrect or undeliverable address should be undertaken by buyer.

Handling Time:

Shipping is usually made in 1-3 business days after payments cleared. Orders are processed from Monday-Friday; Not on the weekends & public holidays.

Sales tax / Customs duties:

Any sales taxes or Customs duties are not included. If came out, they must be undertaken by the buyer. Sales Tax of 8% will be applied for orders shipped within the state of California.

Damage In Shipping:

Email or call us First! We will work with you to get the case resolved in the fastest method.

Return / Refund

If you are not 100% happy with your purchase, please contact Us. Please don't directly opened a request or case without informing us, or else, we will do some discounts on the warranty and other sales-services later on. Hope for your understanding.

Returns & Exchanges

▲

All returns must be made within 14 days of delivery date. Items must be in new, unused condition, with all original materials included with the shipment. A partial refund may be applied for opened or damaged items, depending on the condition.

▲

Items returned under the buyer’s remorse: The return shipping fee must be covered by the buyer; The original shipping cost will also be deducted from the refund. 15% restocking fee of the items purchase price will be charged.

▲

Returns that are the result of our seller's error: Buyer will receive a full refund of the item as well as shipping charges

▲

All returns require a RA (Return Authorization) number that will be given by our seller. Please contact with us at first for more details.

Defective & Damaged Products

▲

If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it's much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. Hope for your understanding.

▲

Replacement or refund of defective or damaged products can only be returned in exchange for the exact same product, or else, the purchase price will be refunded back to your original payment method.

▲

If an item is received damaged, customer service must be contacted within 7 days of receiving your item. All returns require a RA (Return Authorization) number as above.

Payment

eCheck Issues:

Payments via eCheck do not clear immediately. Usually you will wait 5-7 days after checkout for it to clear. Then we will arrange shipments for you.

Warranty & Feedback

▲

6 months' warranty for the machines, not for the consumables. We stand behind our products all the item, so even if your warranty period has expired, you can still seek for service or technical support from us with low cost.

▲

Any warranty shipping cost to us is responsible by buyer.

▲

Any shipping cost to buyer is responsible by the seller.

▲

We committee to the customer satisfaction and want to bring you the best purchase experience. If there is any problems, please contact us ASAP. If not, please leave us a positive feedback as it's very important for us. Thanks very much.

On Jul-17-20 at 20:40:15 PDT, seller added the following information: