-40%

100 SHEETS Pack 13"x19" Silk Screen Printing Waterproof Inkjet Transparency Film

$ 37.75

- Description

- Size Guide

Description

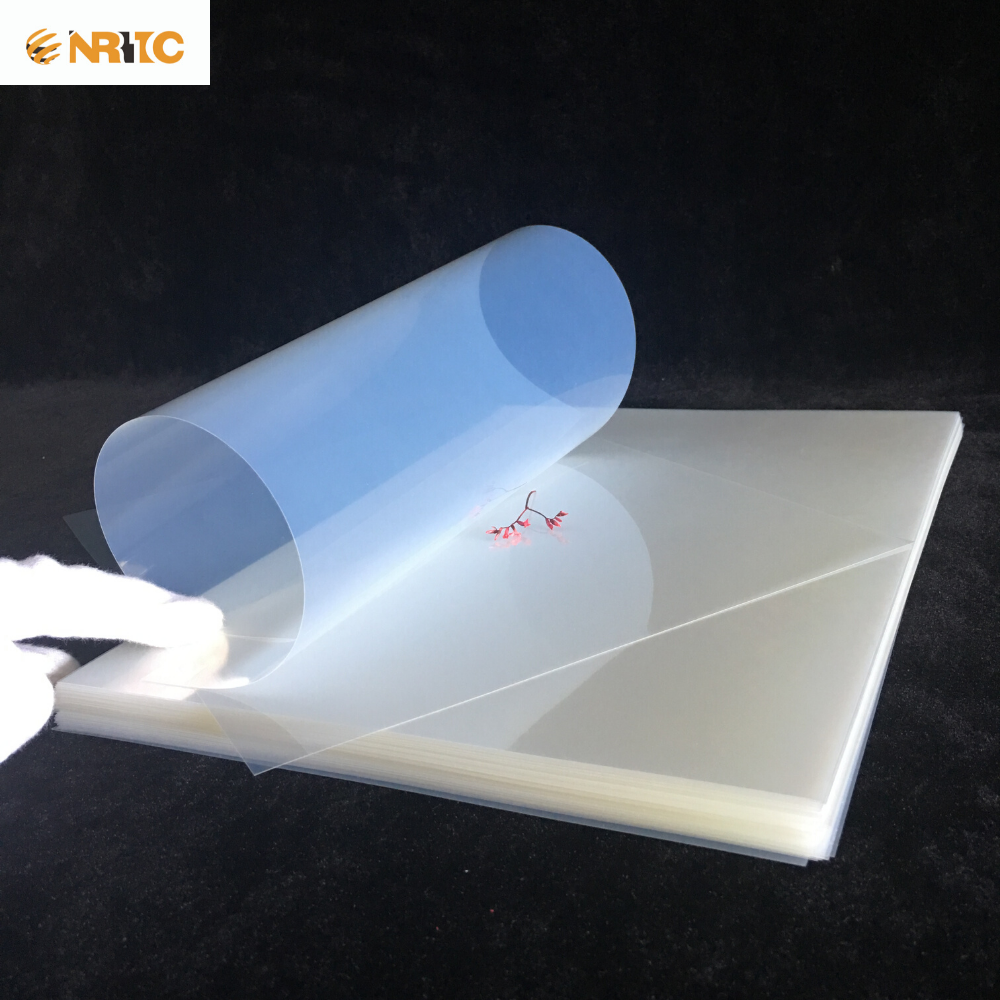

Product Name: A3+Waterproof Transparent Inkjet Film

Material:

100microns PET

Feature:

Waterproof

Thickness:

132microns

Color:

Milky white

Transparency:

Translucent

Processing Type: Injection Molding

Ink support:

Water based dye and pigment

Conglutinate: Non-adhesive

Size : A3+

13” X 19” (483mm X 330mm)

Certificate:ISO14001:2015

Application:

Plate making/Silkscreen printing/Screen Printing/ Off-set Printing/Inkjet Plate Making

Printer Support:

HP/ Epson/ Canon/ Roland/ Mimaki and so on

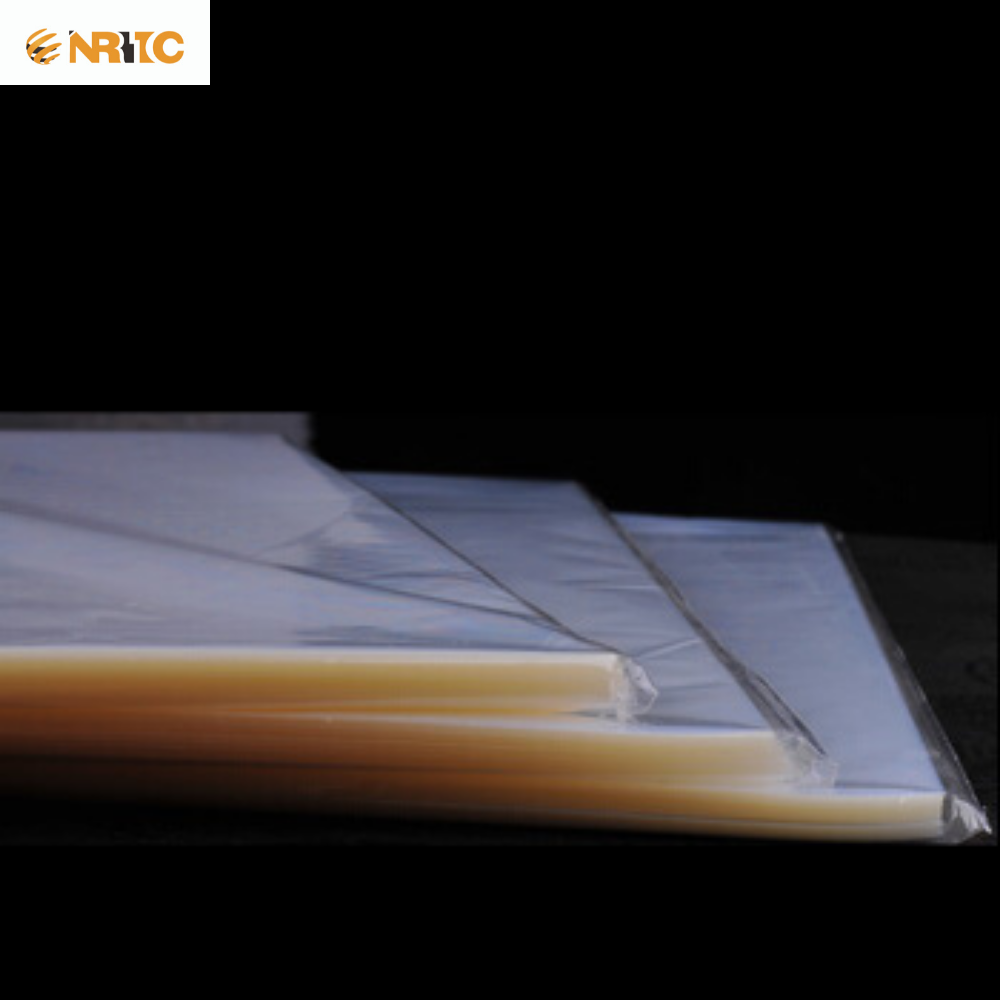

Packaging Details:

For sheet: 100 sheets per bag, 2500sheets/1250sheets per carton and customized package acceptable.

Feature:

1.Excellent waterproofness

2.Anti-curling

3.Non-adhesive

4.Instant drying

5.High black density

6.Sharp dot

7.No inkspread

8.Exceptional precision

9.Color accuracy

10.Support high ink coverage

Technical Data:

Basic Thickness:100microns / 4Mil / 100um / 0.1mm

Product Thickness: 132 micron /5.2 mil

Black Density: >2.5

Haze:14%

Weight:180+/-5g

Storage:

1) Storage temperature should be less than 30

℃

.

2) Storage relative humidity should be 30%-70%.

3) The unprinted Stencil Film should be kept in original package.

4) Keep away from acid, alkali and other harmful gases.

5) Keep away from floor and wall more than 1.5 meters when packed.

6) The Stencil Film should avoid sunshine, damp, great pressure and strike.

7) The Stencil Film should be keep away from pollutant and combustibles.

Applications:

1.Packing Box Printing

2.Textile Printing

3. Instrument Panel

4. Nameplate Printing

5. Glass Printing

6. Ceramics Printing

How To Print

1) Always use high resolution images for best results. 1440dpi for line images, lower is ok for halftone work.

2)Make sure that the film loaded correctly - the coated side face-up under the print head, always print on the sticky side of the film.

3)Always use the highest resolution you can.

4)Always print with inkjet printers.

5)Always print with water based dye and pigment ink.

6)Ink Density - adjust the amount of ink to ensure maximum density while still drying.

7)Drying time - in most cases the ink will be touch dry as the film comes out of the printer. Please leave the Stencil Film alone before completely dry. The completely dry time related to the room temperature and relative humidity.