-40%

TechTongda Screen Printing Machine Curved Silkscreen Machine for Max.180mm Print

$ 126.56

- Description

- Size Guide

Description

180mm Diameter Curved Screen Printing Machine for TubeThis machine is mainly used for arc screen printing of round pipe and round bar products. Suitable for metal, plastic, glass, wood and other materials such as round pipe, round bar;

It is not suitable for printing elliptical pipes and bars.

It is not suitable for the printing of non-smooth products with large dents or bulges on the printing surface and pitting points on the printing surface.

This curved screen printing machine is mainly used for the printing of round tubes and bar type products with diameter of 20-180 mm.

Suitable for printing width within 300 mm; 250mm within length;

Suitable for all kinds of screen plates with outside diameter of 400*350 mm and a thickness of 40 mm.

The machine adopts a push-pull structure, which requires two hands to operate, one hand holding the scraper, the other hand pulling the screen frame, rod following the screen plate moves and rotates naturally, so that the pattern can be printed on the surface of the bar.

The machine is positioned by adjusting the height of the rear main frame , the rear main beam according to the height of the substrate, by adjusting the screen plate main frame and the rear connection screw loose (no need to remove the screw), the overall movement to the strip air up and down to the appropriate position. The upper and lower adjustment range is 160 mm.

Main printer printing frame width is 300 mm, can move from left to right ,the two fixed aluminum strips on the bottom directly installed on both sides of the base, aluminum strip can be moved forward and backward 300 mm; Substrate support frame can be moved around as needed.

The extension frame accessories can be installed on both sides of the main machine. The length of unilateral accessories is 460mm, and the user can install unilaterally according to the needs. The two sides are installed or two sets of supporting frames are combined to connect the main frame on one side; The total width of the main frame and supporting frame is 1200 mm.

The machine is equipped with three sets of roller, respectively for metal bearing roller (diameter: 19mm); Nylon bearing roller (diameter: 25mm); Plastic bearing roller (diameter: 50mm) which can be replaced as needed. Three rollers can be installed on both the main frame and the accessory frame.

The bearing mounting bracket is fixed directly in the aluminum strip mounting hole and can be moved up to 110mm according to the substrate width. 4 additional mounting racks. Remove the bearings from the original mounting racks and fix the additional mounting racks on the main mounting racks directly with screws. The additional mounting racks can be moved up and down 20mm.

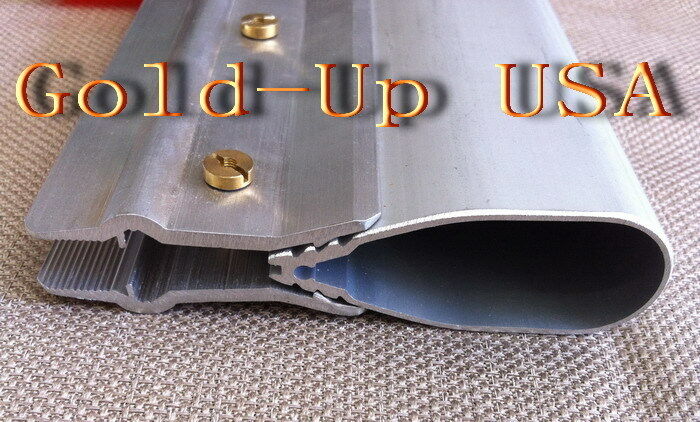

The screen frame with a special handle directly fixed on the screen frame, two installation methods, it can be installed in the upper part of the screen frame,it also can be installed on the side of the screen plate,it is easy to push and pull from left to right, the handle can be arbitrarily fixed in any part of the screen frame, the upper red handle and the front baffle fixed screen plate, to ensure that the screen plate firmly fixed on the handle. The handle fits various mesh frames within a thickness and width of 40mm.

The gravity plate at the rear of the machine can automatically lift the screen plate after printing. It is equipped with two gravity plates, which can be adjusted and installed to balance according to the gravity of the screen plate.Heavy weight can be added to the gravity plate when the front part is overweight.

The upper support frame can control the angle of the upper support frame after lifting, and the lower support frame can be adjusted according to the height of the screen plate. The screen plate is placed parallel to prevent the front part of the screen plate from falling and damaging.

Both supports can be adjusted up and down as needed.

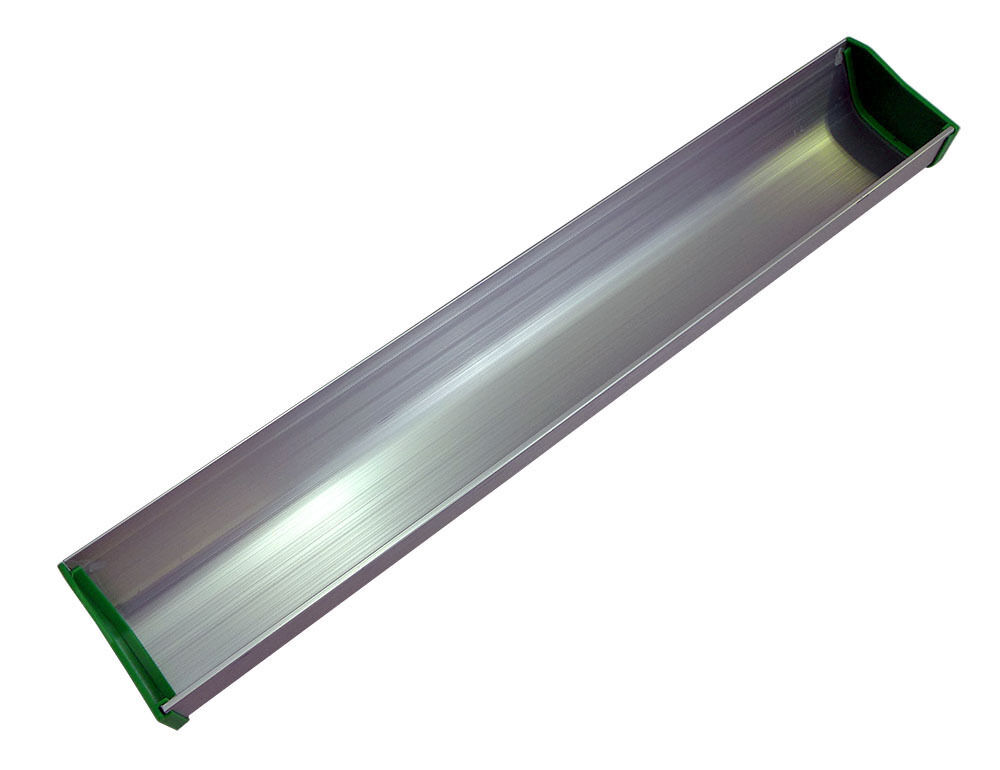

Squeegee rack use self-tapping fixed wooden handle scraper, and it is suitable for the length of less than 200 mm wood handle scraper. The rack can be moved about 250mm according to the position of the pattern of the screen plate.

The screen plate movement distance positioning; Both ends of the two optical shafts are equipped with positioning rings and anti-impact rubber rings. The positioning rings are adjusted front and rear according to the pattern size to reach the appropriate position. Anti-impact apron can be placed between the metal collision issued by the abnormal sound, to protect the machine parts.

The machine is mainly used for printing cylindrical type, cone type products; Such as a variety of plastic, glass, metal materials made of cylindrical, conical shape products, including wine bottles, medicine bottles, cosmetics bottles and other packaging bottles; Mugs, thermos mugs, beer mugs, red mugs, etc. Glass tube, pen ,ballpoint pen, fishing rod, bat and other small cylindrical products;

Usage (for reference only)

1.

Install the screen plate and adjust the support seat under the screen plate to the basic level of the screen plate; Install screen frame pull handle;

2.

Install the scraper and fix it at a distance of 1-2 cm from the pattern;

3.

Adjust the position of the substrate printing frame and roller bearing, place the substrate, and the spacing between the top of the substrate and the screen plate is 1-3 mm; And make the substrate the top and the bottom of the scraper aligned;

4.

Adjust the distance positioning knob of the screen plate according to the left and right dimensions of the pattern;

5.

Put ink into the screen frame;

6.

Press the scraper with the left hand (or right hand); Pull the handle with right hand (or left hand)on the screen frame to print.

Items included:

1 set of 180mm Diameter Curved Screen Printing Machine for Tube(

006594)

Shipping & Handling Details

Default Shipping Cost or Free Shipping Information:

▲

Default shipping cost or free shipping service is only for the customers from Canada or the lower 48 United States by Canada Post, USPS or the UPS Ground. Customers from other areas or needs other shipping ways, please contact us.

▲

Buyers from Guam, Puerto Rico, Virgin Islands, American Samoa, Alaska, Hawaii, PO Boxes, APO/FPO addresses or other countries/areas, there WILL be extra shipping costs, please contact us for more detailed information.

▲

Please make sure your address is valid for both UPS and USPS services. Any costs incurred because of incorrect or undeliverable address should be undertaken by buyer.

Handling Time:

Shipping is usually made in 1-3 business days after payments cleared. Orders are processed from Monday-Friday; Not on the weekends & public holidays.

Sales tax / Customs duties:

Any sales taxes or Customs duties are not included. If came out, they must be undertaken by the buyer.

Damage In Shipping:

Email or call us First! We will work with you to get the case resolved in the fastest method.

Return / Refund

If you are not 100% happy with your purchase, please contact Us. Please don't directly opened a request or case without informing us, or else, we will do some discounts on the warranty and other sales-services later on. Hope for your understanding.

Returns & Exchanges

▲

All returns must be made within 14 days of delivery date. Items must be in new, unused condition, with all original materials included with the shipment. A partial refund may be applied for opened or damaged items, depending on the condition.

▲

Items returned under the buyer’s remorse: The return shipping fee must be covered by the buyer; The original shipping cost will also be deducted from the refund. 15% restocking fee of the items purchase price will be charged.

▲

Returns that are the result of our seller's error: Buyer will receive a full refund of the item as well as shipping charges

▲

All returns require a RA (Return Authorization) number that will be given by our seller. Please contact with us at first for more details.

Defective & Damaged Products

▲

If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it's much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. Hope for your understanding.

▲

Replacement or refund of defective or damaged products can only be returned in exchange for the exact same product, or else, the purchase price will be refunded back to your original payment method.

▲

If an item is received damaged, customer service must be contacted within 7 days of receiving your item. All returns require a RA (Return Authorization) number as above.

Payment

eCheck Issues:

Payments via eCheck do not clear immediately. Usually you will wait 5-7 days after checkout for it to clear. Then we will arrange shipments for you.

Warranty & Feedback

▲

6 months' warranty for the machines, not for the consumables. We stand behind our products all the item, so even if your warranty period has expired, you can still seek for service or technical support from us with low cost.

▲

Any warranty shipping cost to us is responsible by buyer.

▲

Any shipping cost to buyer is responsible by the seller.

▲

We committee to the customer satisfaction and want to bring you the best purchase experience. If there is any problems, please contact us ASAP. If not, please leave us a positive feedback as it's very important for us. Thanks very much.

On Mar-09-21 at 18:48:18 PST, seller added the following information: